Automotive Hardness Testing

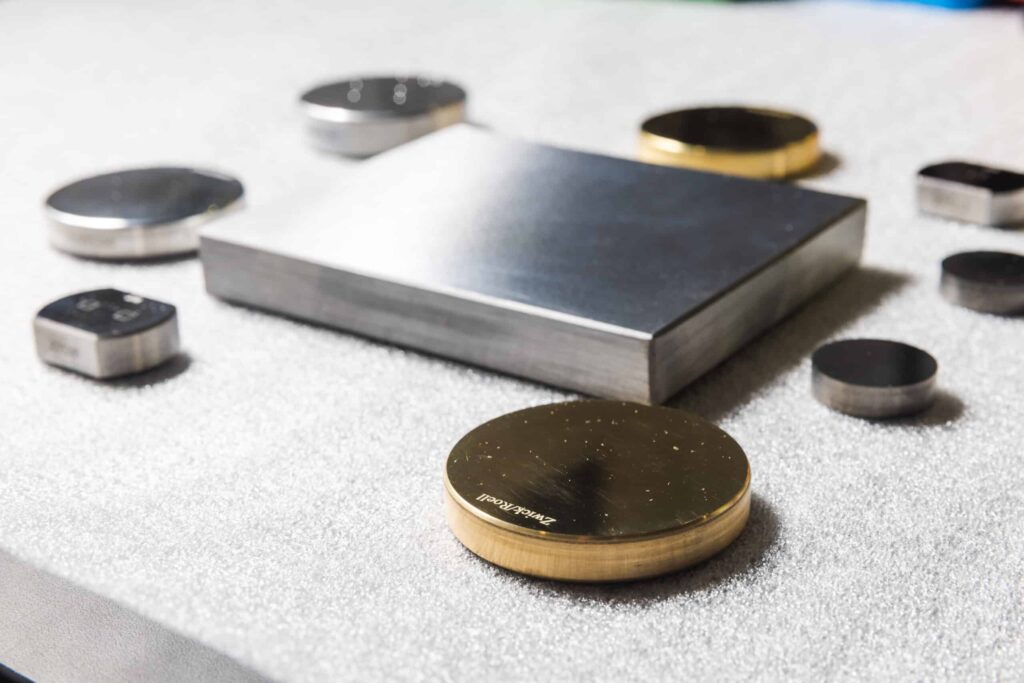

In the automotive industry, hardness testing is a cornerstone of quality control. It ensures materials meet the stringent requirements for strength, durability, and wear resistance essential for vehicle safety and performance. By measuring resistance to permanent deformation or indentation, hardness testing helps assess a material’s capacity to withstand the demands of automotive applications.

Shop now