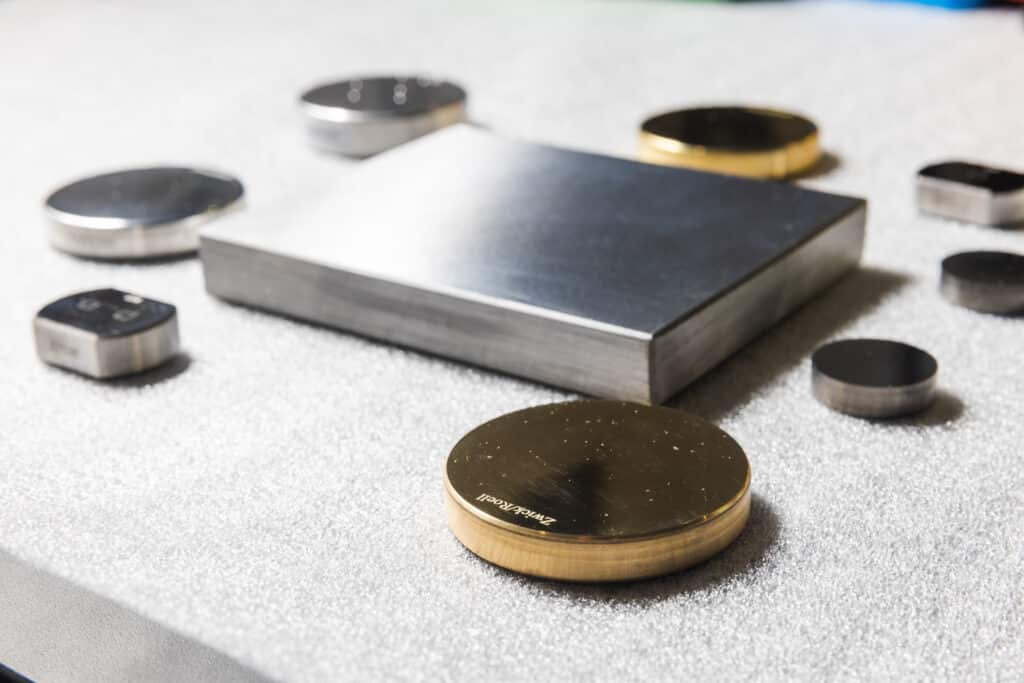

Discover Our Range of Hardness Testing Blocks

The Right Choice for Every Application

Hardness testing is a critical quality control procedure used across various industries to measure the resistance of a material to permanent indentation. It plays a vital role in ensuring the integrity and performance of finished products. But achieving accurate and consistent hardness measurements relies heavily on using reliable test blocks.

At Indentec, we offer a wide range of test blocks that can be used for a variety of industries and operations. We only use high-quality materials with a minimal variation in hardness, ensuring calibration meets measurement as close as possible.

Used to calibrate and verify the accuracy of hardness testing machines, our range of test blocks methods include:

Vickers (HV) – Measures the diagonals of the indentations, allowing you to calibrate the hardness test machine accurately measure to the indentation.

Brinell (HB) – Uses a ball indenter to determine degree of harness, using the diameter of indentation to measure results.

Knoop (HK) – Measure the length of long diagonal of the indentation with its elongated pyramid indenter.

Rockwell (HRC, HRB, etc) – The Rockwell test gauges the depth of penetration under specific load. At Indentec, we provide various Rockwell scales to ensure full compatibility to your test machine.

Discover more about our blocks